Introduction

When you pick up a box of factory ammunition, what you’re holding is the result of hundreds of engineering and quality-control decisions. Manufacturers test every lot to make sure rounds meet safety, reliability, and performance expectations. The three headline tests readers usually care about are pressure, velocity, and accuracy — but the full picture also includes endurance, environmental conditioning, dimensional inspection, and regulatory compliance. This post takes you behind the scenes (at a high level) so you know how modern ammunition is validated before it reaches shooters.

1) Standards and regulation: the baseline

1) Standards and regulation: the baseline

Most reputable makers design tests to meet or exceed industry standards established by bodies such as SAAMI (U.S.) or CIP (Europe). These standards define test procedures, measurement conventions, and how manufacturers report results. Adherence ensures consistency between makers and protects users by setting safe design limits.

2) Pressure testing — the safety backbone

Why it matters: Chamber pressure determines whether a cartridge and firearm combination will operate safely. Excess pressure can cause firearm damage or failure; too little pressure can cause malfunctions.

Typical equipment and methods (high level, non-procedural):

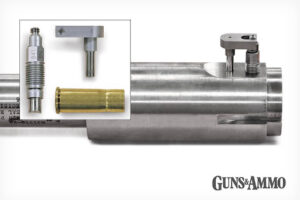

- Piezoelectric transducers: The modern standard. A transducer mounted to a test barrel converts the mechanical pressure from the fired cartridge into an electrical signal that’s recorded by data acquisition systems. This yields a pressure vs. time trace and a peak pressure value.

- Historical/alternate method — crusher gauges: An older technique used deformable elements to derive pressure values. It provided a number historically but is largely replaced by piezoelectric sensors at leading labs.

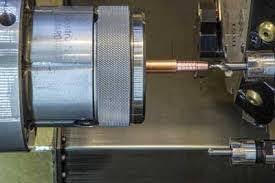

- Test barrels and fixtures: Tests are performed in controlled test barrels and fixtures that mimic firearm conditions without subjecting production firearms to destructive testing.

How results are used:

- Compare lot data to the design and regulatory limits.

- Release/hold decisions for production lots.

- Feed into product development and load tuning.

Note: I’m not providing step-by-step setup details or target pressure numbers because those could be misused. The above explains the concepts and instruments manufacturers rely on.

3) Velocity measurement — performance and consistency

Why it matters: Muzzle velocity affects trajectory, terminal performance, and point of impact. Shooters use published velocity figures for ballistics calculations and zeroing.

How velocity is measured (overview):

- Chronographs are the basic instrument. There are several classes:

- Optical chronographs that detect a bullet passing light sensors.

- Doppler radar systems that track bullet velocity across the flight path and produce highly detailed velocity traces.

- Test protocol: Multiple rounds from a representative sample are shot, typically under consistent environmental and barrel-conditions, and an average (and spread) is reported.

Key metrics:

- Average muzzle velocity for the sample.

- Standard deviation (SD) or extreme spread (ES) to indicate consistency.

- Velocity at set distances (when Doppler systems are used)

4) Accuracy testing — real-world performance

Why it matters: Accuracy testing answers the question: “Where will the bullet hit?” For many customers it’s the primary buying factor.

Common approaches:

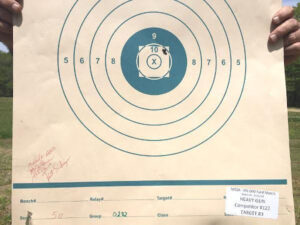

- Group size testing: Shooting a defined number of rounds (e.g., 3, 5, or 10) at fixed distances from a controlled rest to produce group diameters, usually reported as MOA or inches at a specific distance.

- Benchrest vs. field testing: Benchrest rigs provide repeatable mechanical stability for isolating ammunition performance. Field tests (from off-hand or typical shooter positions) show practical, user-level results.

- Barrel conditioning and break-in: Manufacturers account for barrel changes between the test barrel and production firearms and often standardize barrel conditions for testing.

How results are reported:

- Mean group size, standard deviation across groups, and sometimes point-of-impact shift relative to a baseline.

- Data may be broken out by lot or production run.

5) Sampling and lot acceptance testing

Manufacturers don’t test every single round destructively, so they use sampling plans and statistical methods:

- Define an acceptance sampling plan (how many rounds per lot to test).

- Criteria for passing (e.g., allowable number of pressure or ballistic outliers).

- Lot can be accepted, rejected, or held for further testing.

Good quality systems combine statistical sampling with traceability — linking each lot to its raw materials, tooling, and production parameters.

6) Environmental, endurance and abuse testing

Beyond basic pressure/velocity/accuracy, bullets are tested for reliability in adverse conditions:

- Temperature extremes (hot/cold) to see if propellant or primers behave differently.

- Humidity/corrosion exposure for primer and case integrity.

- Endurance testing to run many cycles for feeding/extraction in test firearms.

- Storage-life / accelerated aging tests simulate longer shelf life.

These tests help manufacturers publish suitable storage/usage guidance and warranty claims.

7) Dimensional and material inspections

Quality control also includes non-ballistic checks:

- Case dimensions (headspace, rim, shoulder, overall length)

- Projectile concentricity and runout

- Primer seating depth and crimp consistency

- Powder lot verification and weight checks

- Component metallurgical checks (hardness, tensile testing for specific parts)

Automated vision systems and gauges perform many of these checks inline at high production rates.

Closing / Call to action

Testing keeps shooters safe and ammo predictable. If you’re a shooter, understanding these tests helps you interpret manufacturer specs; if you’re a journalist or engineer, these processes are a good model for how regulated, safety-critical products are validated.

Conclusion

“Ultimately, the rigorous and multi-faceted testing processes used by ammunition manufacturers are what build confidence for every shooter. From measuring pressure with piezoelectric transducers to firing countless rounds for accuracy and consistency, these manufacturers ensure that each round performs safely and predictably. So the next time you head to the range or the hunting blind, you can be certain that the ammunition in your magazine has been meticulously engineered for the highest standards of safety, velocity, and accuracy.”