Introduction:

Keeping ammunition in good, reliable condition is about more than neatness — it’s about safety, performance, and peace of mind. Proper storage reduces the chance of misfires, degradation, corrosion, and accidental damage. This report summarizes what you need to know about temperature, humidity, and container choices for both short- and long-term ammunition storage, plus practical steps, checks, and a simple checklist you can use today.

“Ammo storage that works” refers to a system that ensures ammunition remains safe, stable, and readily available for long-term use. It goes beyond just putting rounds in a box; it involves protecting your ammo from its primary enemies: moisture, temperature fluctuations, and contaminants. Proper storage preserves the ammunition’s performance, extends its lifespan, and protects against potential safety hazards or misuse. Good ammo storage keeps rounds reliable and safe for years. Below is a concise, practical guide you can use now (quick rules, ideal targets, container choices, and simple maintenance).

Why storage matters

Ammunition is made of multiple materials — brass, copper, lead, steel, propellant powders, primers, adhesives, and coatings — each of which responds differently to environment. Problems that come from poor storage include:

- Corrosion of cases or primers (especially with steel-cased or zinc-plated rounds).

- Primer or powder degradation from moisture or extreme heat.

- Bullet separation or swelling if adhesives fail under temperature cycles.

- Change in pressure/ballistics if powder chemistry is altered by heat or humidity.

- Sticking, staining, or surface oxidization that makes feeding or extraction unreliable.

- Safety risks if ammo is exposed to fire or extreme chemical contamination.

Good storage practices maximize shelf life, maintain safe functioning, and make sure the ammunition behaves predictably when you need it.The big environmental factors: temperature and humidity

Temperature — what to aim for and why it matters

Temperature affects powder stability, primer sensitivity, and sealing adhesives. While ammunition can tolerate a wide range of temperatures for limited periods, prolonged exposure to extremes shortens life and increases risk.

- Ideal long-term range: 50–70°F (10–21°C) is commonly recommended for long-term storage. This is a comfortable, conservative band that minimizes thermal stress.

- Acceptable short-term range: Ammunition will survive short exposures from about -20°F to 140°F (-29°C to 60°C), but repeated cycling or prolonged time at extremes is harmful.

- Heat is the main enemy: Elevated temperatures accelerate chemical breakdown of powder and primer compounds and can increase chamber pressures when fired. Long periods in hot attics, hot cars, or near heat sources are bad ideas.

- Avoid repeated big swings: Rapid temperature changes cause condensation and mechanical stresses (expansion/contraction) that can degrade seals and promote corrosion.

Humidity — the silent destroyer

Moisture is the factor that most commonly harms stored ammo because it promotes corrosion, primer fouling, and powder clumping.

- Ideal relative humidity (RH): 30–50% RH is an excellent target for long-term storage. Lower is fine (down to about 10–20% RH), and very low humidity is commonly used for premium long-term storage with desiccants.

- High humidity warning: RH above 60% substantially increases corrosion risk, especially for steel-cased ammo or cartridges with imperfect seals.

- Condensation risk: If warm, moist air contacts cooler cartridges, water will condense on surfaces. This is why temperature control and avoiding rapid temperature changes are both critical.

- Containers: what works (and what to avoid)

Choosing the right container controls environment, organizes inventory, and protects from physical damage.

Military-style ammo cans (metal)

- Pros: Rugged, waterproof with gasketed lid, stackable, available in standard sizes (.30 cal cans, .50 cal cans). Durable protection vs shock and moisture.

- Cons: Can trap moisture if desiccant isn’t used or if sealed while humid; heavy; steel can rust if external finish is damaged.

- Best use: Excellent for medium- to long-term storage when paired with desiccant and stored in a cool place.

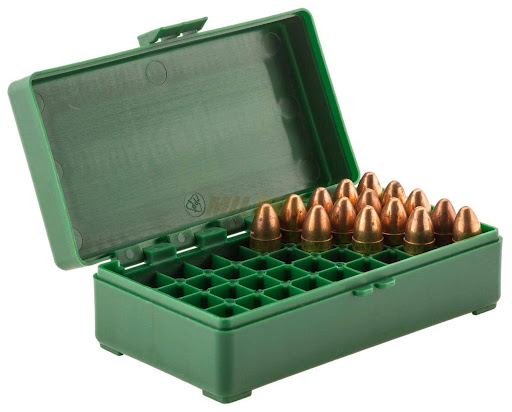

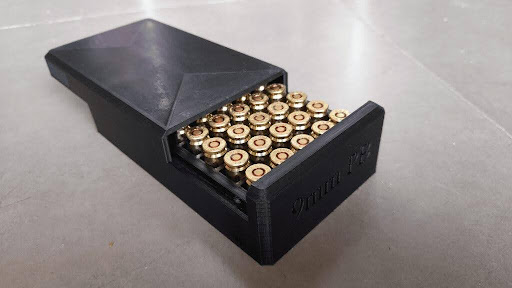

Plastic ammo boxes (polypropylene / hard plastics)

- Pros: Lightweight, corrosion-free, available in many sizes, some are airtight or watertight.

- Cons: Not always as robust as metal; many aren’t rated for long-term airtight sealing; UV can degrade plastic over time.

Best use: Short- to medium-term storage and transport; good for indoor shelving.

Cardboard boxes (factory boxes)

- Pros: Original packaging makes organization easy; inexpensive.

- Cons: Absorbs moisture, vulnerable to pests and water, not recommended for long-term storage.

- Best use: Short-term storage and range carry if kept in dry environment; move to sealed container for longer durations.

Resealable plastic bags (Mylar / heavy-duty zip)

- Pros: Cheap, readily available, can be combined with desiccant; Mylar vacuum bags offer good barrier properties.

- Cons: Zip bags aren’t vapour-proof long-term; puncture risk; not crush-proof.

- Best use: Storage layer inside another sealed container (e.g., individual boxes in ammo can) and for small quantities.

Commercial airtight/clear plastic containers

- Pros: Provide visual inspection without opening; many claim airtight seals.

- Cons: Quality varies — examine lid gasket and seal design.

- Best use: Household storage where frequent inventory checks are useful.

Vacuum sealing and inert atmospheres

- Vacuum sealing: Removes air and moisture and can extend life. Works best when combined with desiccant and a dry starting environment.

- Inert gas (nitrogen) flushing: Often used by manufacturers — replacing oxygen with inert gas reduces long-term oxidation risk but is not commonly practical for casual users.

Controlling humidity inside containers

- Desiccants (silica gel, molecular sieve, clay desiccants):

- Silica gel is widely used; indicator types show when saturated (color change).

- Molecular sieves adsorb more water at low humidity — excellent for very dry storage.

- Regenerate desiccants per manufacturer instructions (oven drying for many types).

- Humidity indicator cards (HICs): Small cards that show RH levels inside sealed containers — inexpensive and helpful.

- Drawer or cabinet dehumidifiers: For larger storage areas, use small electric dehumidifiers (or desiccant-based dehumidifiers) to keep RH in the 30–50% range.

- Vapor-barrier bags / Mylar bags: Combine bags with desiccant and vacuum seal for very low-moisture storage.

- Short-term vs long-term storage strategies

Short-term (weeks–months)

- Keep in factory boxes if environment is cool/dry.

- Use plastic ammo boxes or a metal ammo can for organization and protection.

- Avoid leaving ammo in vehicles or toolboxes for prolonged periods.

Medium-term (months–2 years)

- Move to sealed containers (ammo cans, airtight plastic boxes).

- Add desiccant packs and a humidity indicator.

- Keep in a climate-controlled part of home (closet, basement — see below).

Long-term (years–decades)

- Use airtight containers (ammo cans, Mylar vacuum bags).

- Use high-quality desiccants (molecular sieves or silica gel) and HICs.

- Consider double-layering: sealed bags inside metal cans.

- Store in a consistently cool environment — a conditioned closet or dedicated cabinet away from heat sources.

- Rotate inventory periodically — use “first in, first out.”

Where to store ammo in and around the home

- Best choices: interior closet, cupboard, climate-controlled basement or cellar with stable temps and low humidity.

- Avoid: attics, garages (unless conditioned), near furnaces, water heaters, windows, exterior walls prone to condensation, or in vehicles for storage longer than several days.

- Basement caveat: Some basements are humid — use a dehumidifier and keep ammo off the floor on racks or pallets to avoid flood risk.

- Fire and security: Ammunition should be secured separately from firearms if local law or personal safety practice requires; follow all legal and safety requirements for storage. Store away from open flames, heat-producing equipment, and chemicals.

Special cases and practical tips

- Steel-cased ammo: More prone to corrosion — prioritize low humidity and desiccant. Consider coating with light, non-reactive oil on the exterior if long-term and expect wet storage, but be mindful of handling and fouling implications.

- Tracer or incendiary rounds: Require special attention per manufacturer instructions; typically not appropriate for casual storage due to additional hazards.

- Reloaded ammunition: Ensure components were assembled correctly; inspect seals and crimps; store like factory ammo but be mindful of any special corrosive primers (rare today) that require cleaning.

- Primers and powders: Store powders and primers in their original containers when possible; powders are sensitive to heat and humidity and should be kept in a cool, dry place away from ignition sources.

- Floods and leaks: Store ammo on shelves or cabinets above potential flood levels. In case of water exposure, remove from containers, dry carefully, and inspect for corrosion before use — discard questionable rounds.

Inspection, maintenance, and inventory control

- Periodic checks: Every 6–12 months check seals, desiccants, and humidity indicators. Replace desiccant when saturated; regenerate if reusable.

- Look for signs of trouble: Corrosion, greenish-blue staining, swollen or separated bullets, loose primers, or powder clumps — discard affected rounds safely.

- Label clearly: Date received/purchased, caliber, lot number (if available), and intended use (practice vs match). This helps rotation and traceability.

- Rotate stock: Use older ammo first unless it’s needed for long-term storage; practicing with oldest stock keeps it in use and reveals degradation early.

- Record-keeping: Maintain a simple spreadsheet or notebook: caliber, quantity, purchase date, storage location, special notes.

Safety & legal considerations

- Follow local laws and regulations about storage quantities and securement. (This report doesn’t replace legal advice.)

- Keep ammo away from children and unauthorized persons.

- Don’t store near flammable liquids or in enclosed spaces with potential ignition sources.

- Transport safely: Use sturdy containers; don’t leave lots of ammo unattended in vehicles for long periods.

- Disposal: If you need to dispose of damaged or deteriorated ammunition, contact local law enforcement or a hazardous-materials disposal facility for instructions rather than trying to burn or destroy it yourself.

Common myths — quick clarifications

- Myth: “Ammo lasts forever.”

Reality: With ideal storage life is long (decades possible) but not infinite. Environmental control matters. - Myth: “Putting ammo in the freezer preserves it best.”

Reality: Freezing can be okay short-term, but condensation during thawing is the real risk. If used, ensure vacuum-sealed, desiccated packaging before freezing and allow slow equalization to room temperature inside sealed container. - Myth: “All desiccants are the same.”

Reality: No — some absorb more water and perform better at low RH. Molecular sieve is superior for very dry long-term storage; silica gel is common and effective.

Quick, practical checklist (do this today)

- Move opened factory boxes to a sealed ammo can or airtight plastic box.

- Add an appropriate-size silica gel pack and a humidity indicator card.

- Store the container in a cool, interior location away from heat sources.

- Label each container with caliber, quantity, and date purchased.

- Schedule an inspection every 6–12 months to check desiccant and HICs.

Conclusion

Good ammunition storage is a straightforward combination of controlling temperature, limiting humidity, and choosing the right container. Aim for stable, moderate temperatures (roughly 50–70°F / 10–21°C) and relative humidity around 30–50% for most situations. Use rugged, gasketed ammo cans or high-quality airtight containers with desiccants and humidity indicators for reliable protection. Inspect periodically, label and rotate stock, and keep storage away from heat, moisture, and unauthorized access.

Follow the practical steps in the checklist above and you’ll significantly extend the reliable life of your ammunition, reduce safety risks, and avoid unpleasant surprises at the range.